Profitable digitalization, Open network, increase performance, ensure security projects start in the machine network

Open network, increase performance, ensure security

Open OT networks securely - implement digitization efficiently

Lifting the digital data treasures of the store floor level

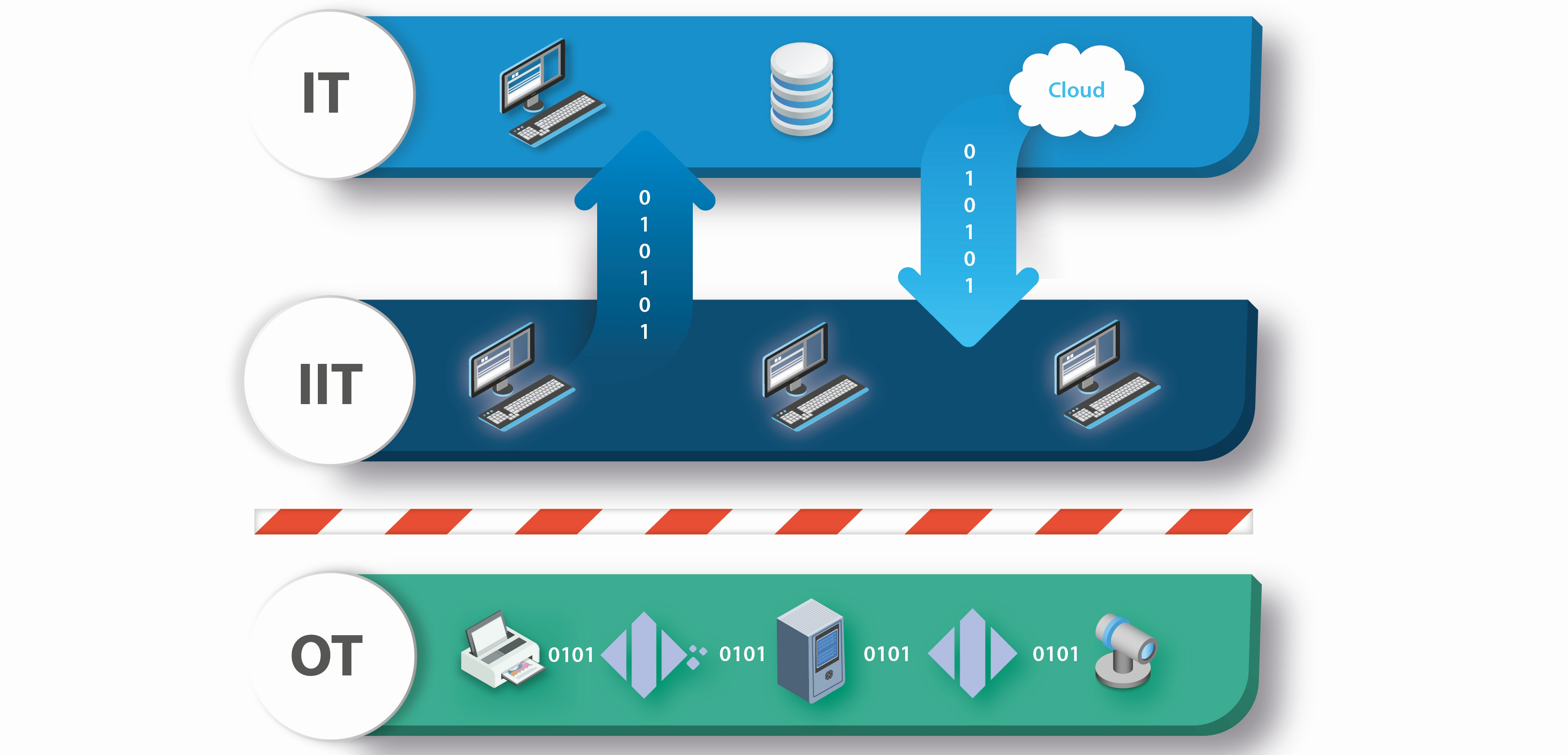

Anyone who wants to implement digitization projects, e.g. for energy management, inventory, condition monitoring or preventive maintenance concepts, knows the challenge: How do we get the data? The controls of machines and plants, the actual source of data, are often associated with self-contained networks and deny themselves any access from the outside. And this is by no means out of ill will, but because security and functional reliability are equated with isolation. However, anyone who wants to drive digitization projects forward efficiently should be able to use as much of the data as possible that is already available in machines. In this context, the network as a whole plays a central role. It must be well planned, sensibly segmented, optimized to the respective requirements, monitored and, above all, understood as such.

Today, however, a good 50% of digitization projects are doomed to failure (source: www.service-report-it.de) or are at least severely restricted or postponed for cost reasons because the resources to be expended on data acquisition exceed the planned budget. For example, in energy management, data is currently obtained using additional energy meters and queried via a separately installed network. These additional cost drivers make the project complicated, confusing and require additional maintenance and servicing.

Our adjusting screws for your success

- Plan OT networks according to the requirements of function and digitization

- Intensification of the exchange between operator and installer

- Highlighting data treasures - leveraging existing resources

- Bringing IIT and OT together without hurdles and barriers

- Determining responsibilities

- Establishment of access rules, their control and implementation

Advice? Technical questions?

We are happy to support you in gaining the maximum added value in your digitalization project.

Matthias Winderlich

Head of Engineering and Support- +49 34491 580152

- Send an email

Achieve your digitization goals with us

Efficient energy

management

- Avoidance of load peaks

- Identification of nominal current deviations

- Consumption forecasts for purchasing optimization

Permanent

condition monitoring

- Reduction of throughput times

- Avoidance of downtimes

- Securing availability

Preventive

maintenance

- Avoiding breakdowns

- Guarantee network stability

- Be able to act before it is too late

Automated

inventory

- Overview of all assets and vulnerabilities

- Exposure of the security vulnerable devices

Further information

Case studies for effective generation of data from the shopfloor

Anyone who wants to implement digitalisation projects at the shopfloor level, such as energy management, condition monitoring or preventive maintenance concepts, knows the challenges:

Where do I get comprehensive and precisely fitting data? How can I keep the costs for infrastructural adjustments at a reasonable level?

» Read on now!