Case study device manufacturing Food & Beverage

with Miele/Imperial Werke

Tracking down the causes of communication issues

OT diagnosis switches improve transparency of the steamer production line

Time is essential in automated production. Plants must work reliably every day in order to manufacture products economically. Every standstill costs money. If any errors occur, the first thing to focus on is the mechanics and whether sensors, actuators and control technology are doing their job. However, the network is still not seen in many places as a relevant part of a resilient system. “Troublemakers” may certainly develop and cause errors that cannot be easily reproduced. The employees of the maintenance team at Imperial-Werke in Bünde are able to confirm this from their own everyday work.

Gas and ceramic hobs, (pressure) steam stoves and warming drawers are manufactured at Miele’s Bünde plant. About 700 employees work at the site, and approximately 500,000 devices leave the plant every year (Fig. 1). The operating technology team ensures smooth and safe production on site. However, sporadic and unclear network failures can still cause downtime in the production line for steam cookers. The maintenance staff wanted to get to the bottom of these.

Creating transparency

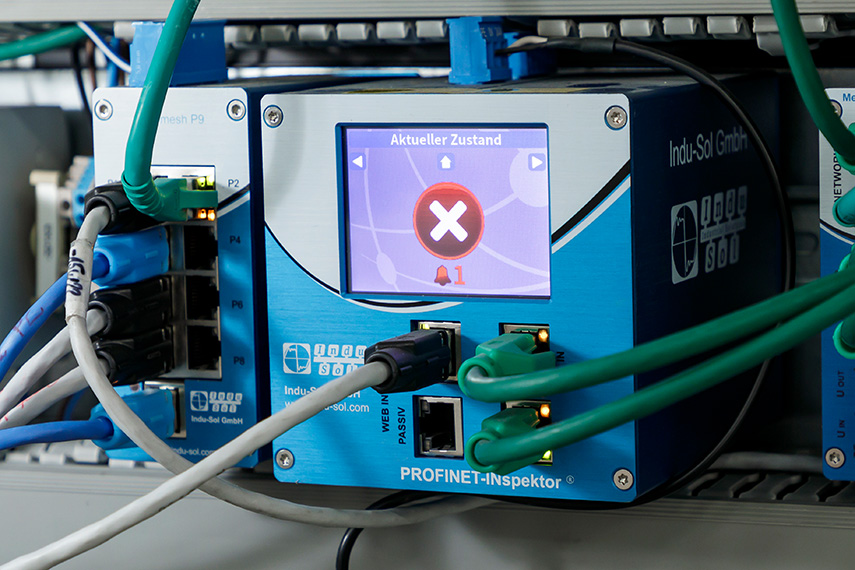

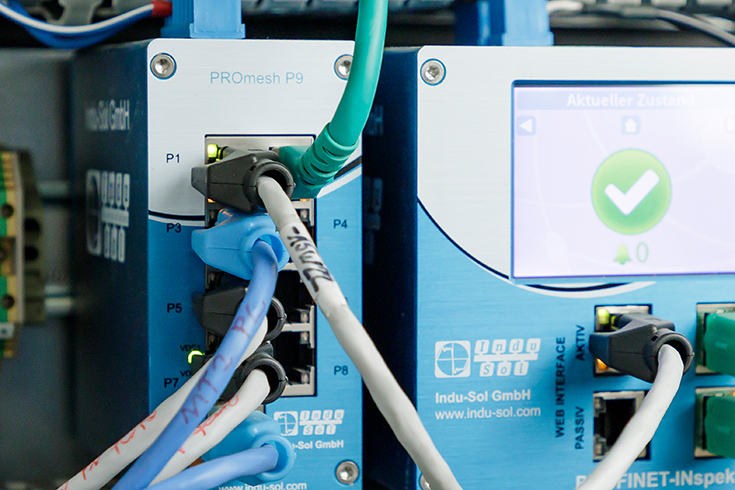

Stamped stainless steel sheets for cooking chamber production are fed in, to be converted to cooking chambers for steam cookers via various forming and welding processes. In the automated system, individual robot cells are interlinked, and the blanks are passed from station to station. Roughly every two minutes, a new cooking chamber leaves this production line for final assembly. Jan Rüter (Fig. 2), Head of Plant Engineering at Miele’s Bünde plant, sketches the situation: “We kept experiencing sporadic failures and couldn’t track what was causing them. Since we suspected that the entire network was at fault rather than any individual machines, our colleagues from our plant in Bielefeld lent us their PROFINET inspector. That was a first important step towards finding the cause!” Evaluation of these data confirmed that the fault was in the communications network, or, more specifically, the EMC. PROmesh P9 and P20 type industrial Ethernet switches were used to keep a permanent eye on equipotential bonding. Its leakage current monitoring detects the exact time, frequency (sampling rate of 25 KHz) and intensity (measuring range from 0 to 10 A) of EMC couplings in data lines (Fig. 4). There was another major advantage here as well: The switches are managed to enable access to the communication data. This forms the basis for the permanent network monitoring (Fig. 5) offered by the PROmesh switches.

Fig. 2: Jan Rüter, Head of Operations Technology at Miele in Bünde: “We kept experiencing sporadic failures and couldn’t really track what was causing them.” (author: Miele)

Fig. 2: Jan Rüter, Head of Operations Technology at Miele in Bünde: “We kept experiencing sporadic failures and couldn’t really track what was causing them.” (author: Miele) Fig. 3: The PROFINET-INspektor helped in the first step to confirm that the errors had their cause in the network communication. (author: Miele)

Fig. 3: The PROFINET-INspektor helped in the first step to confirm that the errors had their cause in the network communication. (author: Miele)This helps in tracking down sporadic non-reproducible events and their causes and thus keep an eye on network performance. Data loss (discards) occurs when the data traffic in the network exceeds the performance limit of a switch. They are displayed as port statistics on an integrated web interface together with errors, error telegrams netload/ms. “We are now also able to determine the causes of our problems,” explains Wilhelm Kröger (Fig. 6), team leader for machine and plant technology at the Bünde plant. “We have large interference currents in phases, and they ultimately affect network communications since we use many welding applications.”

From IT to OT switch

Classic IT switches were installed at Miele’s Bünde plant in the past. They were managed by the IT department. This brought several disadvantages at once: The maintenance department staff did not have any access to the switches. The switches also do not meet the OT requirements for PROFINET certification, Netload Class (robustness against the network traffic to be processed) and Conformance Class (scope of PROFINET functions). At the same time, these switches do not offer any diagnostic functions, such as leakage current measurement. These would help with operation of an OT network. However, before any new switches are deployed in a larger enterprise, it’s not just maintenance that needs to be convinced by the hardware. The support responsibilities of individual production areas also had to be rethought together with IT. “There are, of course, many requirements such a device needs to meet before we can use it. It was a relief for us that we could first borrow a switch from Indu-Sol and test it extensively.” The tests very quickly showed that causes of network faults, still unknown at the time, could be made transparent quickly and easily. The network experts also developed a firmware add-on to meet Miele’s IT security requirements to enable final deployment.

Horst Voigt (Fig. 7), key account manager at Indu-Sol: “It is important to us to be able to offer our customers an ideal solution. If the client involves us in the decision-making process as well as Miele did, such individual adjustments are easy enough to implement.”

However, the manufacturer’s maintenance staff also found the advance training useful. They are essentially electricians, rather than network experts. Therefore, Indu-Sol not only instructed the maintenance team in the use of the switches, but also provided all essential content on the subject of data networks. Mr Kröger recalls: “What are the technical terms? What difficulties may appear? How do they become evident? How can we fix them? We have quickly gained an insight into the “secret machinations” of the network. It was very helpful. It is just as useful that we are getting answers and support from the network experts when we have specific questions, which usually only arise in our day-to-day work.”

Creating transparency is the first step towards finding a solution

Only those who know their problem can solve it. At the same time, just because you’re aware of its causes doesn’t mean a problem is solved. The manufacturer’s welding applications require high-frequency ignition. This generates electromagnetic interference radiation, which also affects data lines. This results in data communication problems that disrupt the sequence of individual manufacturing steps or cause them to be performed incorrectly. For example, data packets will be lost, leading to abnormal plant behaviour or, in the worst case, downtime. Rüter explains: “Now we are working on replacing plasma welding with a process that offers the same speeds and quality while generating less leakage current. Of course, this is not a trivial task.” As the example shows, not all sources of error could simply be eliminated or mitigated. Therefore, the maintainers are also interested in knowing about other people’s experience at this point and possible solutions for the causes of network communication issue. “We would also be happy to exchange information with maintenance staff from other companies on their experiences and approaches to solutions here,” says Rüter.

Fig. 8: PROmesh switches in the central control cabinet of the steam oven production line at Miele (author: Imperial)

Fig. 8: PROmesh switches in the central control cabinet of the steam oven production line at Miele (author: Imperial)

Simple integration

Once the decision to use new switches was made, the next step was, of course, their integration. All in all, integration of the PROmesh switches was very simple (Fig. 8). Dirk Blöcker, an operating technician at Miele in Bünde, Germany, remembers: “Since we installed all of our switches in a remote control cabinet rather than directly in the plant, we only had to replace them at one point. We prepared the exchange well together with Indu-Sol. It only took a little over half a day for the plant to return to productive operation.”

The manufacturer of built-in kitchen appliances was happy with the transparency this added to their network communications with the new switches. The maintenance employees are also grateful for what they have learned along the way. While some brought plenty of prior knowledge to the table, all of them learned a lot of helpful information on network communication in a short time through the training and the exchange with Indu-Sol. This deeper understanding also ultimately ensures fail-safe production today, with high-quality products at the end of the line. Blöcker summarises: “Our practical experience shows that the boundaries between machine and IT networks are becoming less and less clear. Therefore, it is going to be important in future that maintenance staff understand more and more about network communication and also have access to the production network. In the end, the right switch is the key to success here.”

About Miele

Miele is the world’s leading supplier of premium domestic appliances for the cooking, baking, steam cooking, refrigeration/freezing, coffee preparation, dishwashing, laundry, and floor care areas. They also make dishwashers, air cleaners, washing machines, and dryers for commercial use, as well as washer-disinfectors and sterilisers for medical facilities and laboratories (Professional business area). Founded in 1899, the company maintains eight production sites in Germany, one plant each in Austria, the Czech Republic, China, Romania, and Poland, as well as the two plants of Italian medical technology subsidiary Steelco Group. Sales in fiscal 2020 amounted to around 4.5 billion euros (of which in Germany: 29.5 percent). Miele is represented in almost 100 countries/regions by its own sales companies or through importers. Now in its fourth generation, the family-owned group employs around 20,900 people around the world, with about 11,050 of them in Germany. Headquartered in Gütersloh in Westphalia.

Do you have questions?

Don't hesitate to contact our expert.

Michael Röhler

Teamleader Technical Sales- +49 34491 580-186

- Send an email