Leakage current

Leakage current is electric current that builds up at impacted or ineffective isolators and flows through conductors that are not intended for that. "Leaks" can occur in all electric systems – whereby special sensitivity needs to be applied in power supply plants, in vehicle mechatronics, in building lightning protection as well as in production machine or plants. Often leak currents appear as creepage current which spread on the surface of faulty or damaged isolators. In industrial environments, you talk about leakage current when undesired currents spread through inductive, capacitive or galvanic couplings on shielded lines or the equipotential bonding (PA). Couplings into high- and low-voltage conductors occur frequently, for instance if motor and data lines are routed close to each other. High-frequency conductors, which can be found in modern process automation, promote such couplings.

Wherever leak currents flow, they cause problems: They drain batteries for example, reduce the capacities of capacitors, cause residual current devices to switch off, impede sensors and thus interfere with the function of entire machines or plants. If leak currents get onto the shielding of data lines in process automation, they are a hindrance in three aspects:

Coupled-in currents can also lead to an increased wear of frequency controlled three-phase drives if they flow from the stator via the bearing, shaft and the PA system back to the frequency inverter. A typical pattern of damage is the wear on bearing rings that suffer from spark erosion from high-frequency current pulses.

Service technicians face the challenge of avoiding or minimising leak currents in the sense of a continuous production. It needs to be clear to them, however, that the awareness of the problems for their side effects has not sunk in yet with all those who are responsible. Discharge currents are sometimes just considered – undifferentiated – as an "unavoidable phenomenon" in electric systems. The need for action is increasing steadily though: Due to the increasing number frequency-regulated drives and the increasing degree of automation of the machines or plant, field loads and unwanted shield currents are becoming increasingly more relevant sources for faults. To keep this problem under control, the routing of symmetrical motor cables, combined with professional, expert installation of an earthing and equipotential bonding system is a necessary foundation.

Keyword: Symmetric motor cable

As opposed to conventional motor cables, the PE conductor is not routed parallel to the three phases here, but is split into three lines. With this structure of the three lines, with their phases shifted by 120° to each other, the coupled-in currents nearly cancel each other.

Building upon that, machines and plants need to be checked regularly for leak currents; optimally they should be monitored. Current measuring clamps are suitable measuring devices that determine the difference current between outgoing and return conductors. It is important that the clamps feature a broad enough measuring range. The leakage current clamp EMCheck® LSMZ I from Indu-Sol with its frequency band of 50/60 Hz or 5 Hz to 1 kHz is therefore designed especially for measuring leakage and shield currents. With their help, impacted isolators can be located even in inconvenient installation positions. Thanks to their wide clamp opening, the LSMZ I can be applied over all common motor, data, protection and 24 V DC supply lines.

The same is valid for the intelligent current measuring clamp EMCheck® ISMZ I which offers several additional functions compared to the LSMZ I. This includes the recording function that records the current course for every scanning time and displays it on a time scale. Its frequency band of up to 20 kHz makes it possible to precisely scan the current course so that the frequency spectrum of the leakage or shielding current can be mapped (see adjacent figure). Equipped with a powerful battery and an ample data memory, the ISMZ I is capable of recording the measurement data for a duration of up to 14 days and to provide them for retrieval. It can remain continuously at the measuring point during the time frame.

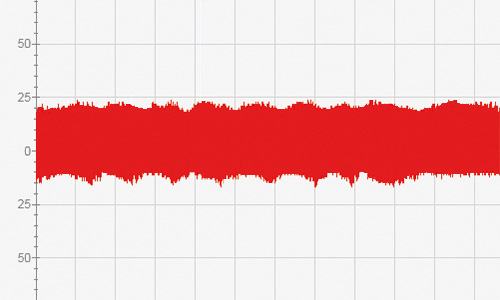

LSMZ I: Current course with effective value measurement in the frequency band up to 1 kHz

LSMZ I: Current course with effective value measurement in the frequency band up to 1 kHz

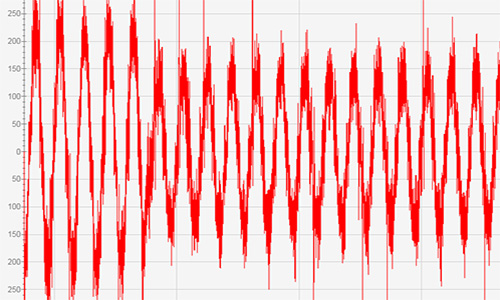

ISMZ I: Current course with peak value measurement in the frequency band up to 20 kHz

ISMZ I: Current course with peak value measurement in the frequency band up to 20 kHz

Both measuring clamps differ additionally in their resolution of details: Whereas the LSMZ I determines the current course using effective values, the ISMZ I records the current course with its sampling rate of up to 40 kHz precisely to the amplitude – i.e. including peak values. Thus sporadically occurring interference peaks can be detected which are overlooked by conventional current clamps. A further advantage of the ISMZ I lies in its integrated intelligence: In a "teach phase" it automatically detects suitable threshold values for leakage or shielding current measurement. Once detected, the operator can use them as reference points (triggers) for the temporary recording. Evaluation of the recorded data is done conveniently afterwards by software on a laptop or a PC.

For permanent monitoring of several cables in industrial production the EMV-INspektor® V2 can be used. The measuring and diagnostic device from Indu-Sol can analyse up to four lines with a sampling frequency of 50 kHz and is intended for being installed on top-hat rails. The visualisation and analysis of the recorded data is done conveniently in the web interface where the current course of each individual measuring channel is displayed at various scales.