Condition Monitoring for Industrial Ethernet and Fieldbus Networks

Application-comprehensive. Scalable. Modular.

Do Not Leave Your Availability to Chance

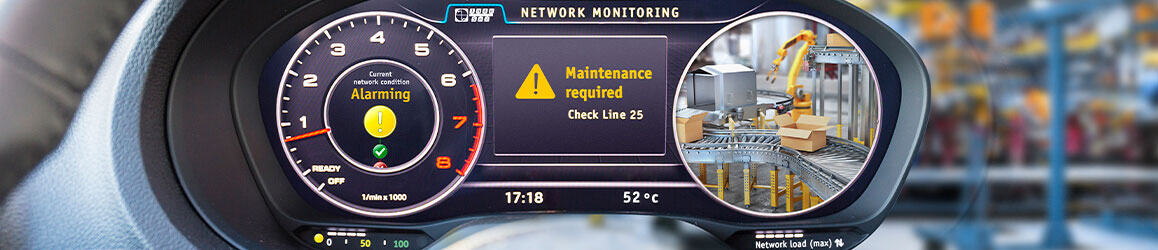

Permanent condition monitoring has become a staple in many areas of everyday life. We often are so used to it that we barely noticed it anymore. On-board diagnostics in modern passenger cars are one example for this, where all operationally relevant conditions are monitored seamlessly even though we are not made consciously aware of this while everything is going smoothly. If any irregularities occur, such as insufficient tyre pressure, we will be informed before the issue turns critical.

Your cockpit for maximum availability

Network-comprehensive OT monitoring for PROFINET, PROFIBUS, etc.

A similar situation is present in industrial networks and fieldbuses. Without an application-comprehensive monitoring solution, you would only be able to start reacting to incidents when it’s already too late. Only an integrated network monitoring system can make condition changes visible across all systems early on. Availability of complex systems and processes can be guaranteed in a targeted and foresighted manner. Reduce your effort by keeping your various systems centrally in view in an OT monitoring solution. Choose flexibly which systems and machines you want to protect.

Use the monitoring advantages in your machine networks as well. Create the prerequisite for high long-term availability of your machines and systems by being able to react to any incidents quickly as they occur thanks to the integrated alarm function.

Do you have any technical questions?

Do you desire personal advice?

Frank Lehmann

Product management

- +49 (0)34491 / 5818-120

I will gladly help you find the right monitoring solution.

Central Application Monitoring for Your Ethernet and Fieldbus Systems

Practical benefits and advantages for your plant operation

What makes permanent condition monitoring so very effective?

- Notice and fix gradual reduction of network quality

Individual non-critical fault conditions often affect your overall system’s efficiency or resilience without being noticed. Condition monitoring allows you to detect such fault conditions quickly to correct them before your plant gradually nears critical condition. - (Pre)warning when operationally dangerous events occur

The monitoring system will automatically trigger a visible warning if potentially critical events occur. This gives you valuable time to prevent further faults or consequential damage. - Targeted localisation of interference sources

Some issues happen without any early indicators. Full data acquisition of a monitoring system will support targeted troubleshooting anyway. Based on the available data, error patterns leading up to the fault can be evaluated right away in great detail, similar to the function of an aircraft black box. - Maintenance and troubleshooting by remote monitoring (Secured Remote Access)

Reduce service costs and delays caused by to travel time. Remote monitoring makes it possible for authorised specialists to provide targeted support in securing or restoring your availability. Choose how permanent or temporary you want this service to be.

Additional information: Reasons why you should be using network monitoring as well.

Combination options/expansion stages

The flexible monitoring solution that fits your requirements

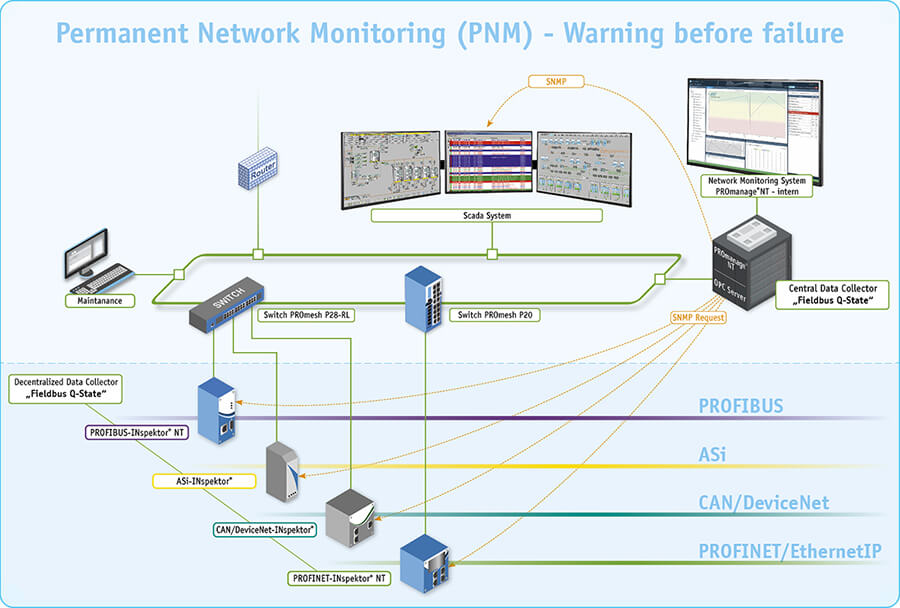

- One application, one system

Keep an eye on individual system areas or machines with network-specific analysis devices (decentralised data collectors) such as the PROFIBUS-INspektor® NT and enjoy the advantages of combined status monitoring and telegram depth analysis. Optional integration in monitoring software PROmanage® NT possible. - One application, several systems

Are you using several systems from the same process network (e.g. PROFINET)? You can monitor them individually or combine your analysis devices (decentralised data collectors) in one central monitoring software. - Several applications, one system

Do you use multiple applications (PROFINET, PROFIBUS, etc.) in a single system? Monitor them together in the convergent network with the higher-level Ethernet communication and keep an eye on all parameters connected to the system. - Several applications, several systems

Reduce your monitoring effort by consolidating all analysis and monitoring data of your systems in one central location by using PROmanage® NT and the compatible data collectors of your choice. - Monitoring without any additional hardware

Get basic monitoring of your Ethernet-based machine network using your available infrastructure without installing any additional analysis hardware. » Tell me more

Example configuration (click to enlarge)

Example configuration (click to enlarge)

Greatest flexibility and scalability

Network monitoring that grows along with your needs

Has your system changed? Do you have any new systems/parts to be monitored? Have your requirements changed recently? The network-comprehensive monitoring solution by Indu-Sol keeps you safe.

Profit from perfectly interlocking components and seamless integration into your central monitoring solution. Combine analysers (data collectors like the PROFINET-INspektor® NT), managed switches, and the PROmanage® NT monitoring software just as you need them. Expansion or combination of individual monitoring components is possible at any time..

Your path to your optimal monitoring solution

Indu-Sol’s recommendation for action

Implementing a central monitoring or management solution for industrial networks can be quite the challenge. We would like to support you in choosing your OT network monitoring solution based on the following questions.

- System-comprehensive network monitoring or protection of critical system areas?

Choose the network areas to be monitored and protected. - Basic monitoring or monitoring with deep analysis?

Are you looking for basic monitoring for your Ethernet machine network, or do you need a detailed look into your application’s data communication? Simply combine the advantages of both options. - Do you need remote monitoring? (remote access)

Do you want to be able to access all condition and performance data from your control room? Spare your maintenance and external service partners the journey to your site by adding individual remote service options.

Alternatively, our experts will be happy to accompany you from solution selection to implementation on-site. » Request expert advice now

What products are a good match for me?

Network monitoring product overview

Explore our product range for professional condition monitoring of your system and machine communication, from PROFINET to the AS interface.

Central monitoring software for industrial networks and fieldbus systems

- PROmanage® NT

» Learn more about the central monitoring software

Choose your plant network