Network monitoring

– Explaination and definition

Network monitoring is frequently viewed by outsiders one-dimensionally as the task of IT administration in the assumption that networked computers and devices can primarily be found in office communication. Network technology plays a leading role though also in industrial communication. The technological progress in the production process promotes an increased networking. Driving factors behind this development are programmable logic controllers, efficient communication media, devices and machines that are becoming more intelligent as well as increasingly more powerful software for linking their data. At the threshold to Industry 4.0, networking is taking place not only horizontally but also vertically – that is between production and office. These are new challenges for planners, installers and operators as well as repair technicians or service employees.

The thorough transition does not stop at the concept of network monitoring: The main focus to date was to record complex network structures and data paths, to document their status and to ensure their continuous availability, yet in the future quality assurance and the guarantee of security will gain importance. The more autonomous machines work and exchange amongst each other, the more the proportion of acyclic communication will increase versus cyclic communication, which will make condition monitoring and risk analysis significantly more difficult. Additionally, networks that are getting larger offer more access points for manipulation due to the merging of automation technology and IT. A permanent network monitoring (PNM) must therefore answer the following central questions: Who communicated what with whom when by which means? Only when the repair technicians have access to all this information can they effectively handle the causes for malfunctions and the security problems.

The foundation of an effective monitoring is therefore the central bundling of historical and accurate status data of a network and its devices. In order to not create even more "traffic" and thereby increase the network load even more, the employment of passive measuring and diagnostic devices is recommended for the monitoring. As extended arm of the technical personnel, the devices of the INspektor® family of Indu-Sol thus permanently analyse the logical data traffic feedback-free in the respective network. With that they can practically provide information "first hand" about the most important parameters of the communication quality. The collected data is collected, fieldbus-spanning, at a central point using the network monitoring software PROmanage® NT. This allows the user to analyse the current network status at any time. Likewise he can review the historical status data. A condition-based maintenance can be implemented therefore in PROFIBUS as well as in the PROFINET-, ASi- and CAN-based networks. The respective INspektors® are attuned to the peculiarities of the network types and their characteristic parameters.

In addition to the permanent diagnosis of the data traffic and the security, observation of electromagnetic influences and the equipotential bonding belong to a comprehensive network monitoring. No system is ultimately immune to interference currents along fieldbus cables, encoder lines, equipotential bonding systems or voltage supply cables. That is why Indu-Sol has developed the EMV-INspektor® V2 diagnostic device. It permits automated, contact-free and interruption-free tests during operation and records permanently as well as temporarily occurring electromagnetic malfunctions in up to four simultaneously connected measuring channels. The collected values are recorded by the device separately for each channel so that a clean analysis is possible.

Permanent network monitoring makes condition-based maintenance possible

Permanent network monitoring makes condition-based maintenance possible

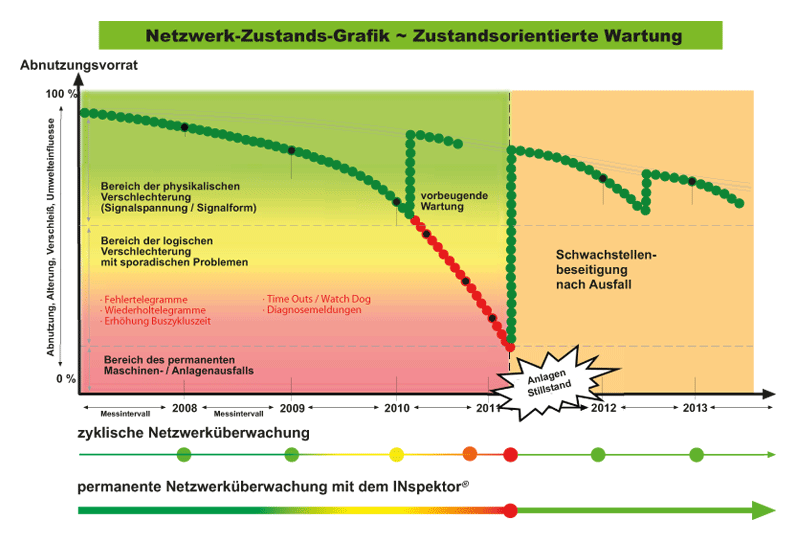

Why there is no alternative for the concept of permanent network monitoring at the transfer to Industry 4.0 is made clear by a look at its alternative to date: the cyclic measurement. It is outdated simply because it does not permit a condition-based maintenance and ignores the fact that machines and plants do not wear out linearly. As long as the network status is monitored in (rigid) intervals, there is always the risk that short term deteriorations of physical or logical parameters remain unnoticed. If the interference reserves during the measurement lay maybe still within the range of sporadic interferences, they can fall into the range of permanent interferences by the next inspection date – a sudden failure can no longer be ruled out. Maintenance turns into repair.

A permanent network monitoring in which the measured values are recorded in real-time provides information about the current interference reserves at any time. Thus maintenance becomes plannable and repairs are the exception. The operator saves not only repair costs but also achieves a higher system availability and production continuity as compared to the cyclic measurement.

Stay informed! Receive the latest offers and news about industrial networks and their optimization - conveniently via e-mail.