Maximum plant availability through Condition Monitoring and Predictive Maintenance

This is because the downtime costs caused by total breakdowns or recurring disruptions in the recyclables stream can wipe out a large part of the planned operating profit. With predictive maintenance, the reasons for many breakdowns can be identified well in advance and can be dealt with using a structured maintenance process.

An average of 600,000 € more operating profit per plant and up to 90% fewer breakdowns are possible

Over the past 20 years, we have gathered our experience in around 1,800 SOS operations in almost all branches of industry. The conclusion: almost all failures in the machine network could have been detected and avoided in advance. We estimate that this resulted in a total loss of around 2.3 billion € for the affected industrial companies. So-called indirect maintenance costs.

How can indirect maintenance costs be converted into operating profit?

With a Condition Monitoring Management System (CMMS) you get a permanent view of what is going on in the OT network and in the application (PROFIBUS, PROFINET or Ethernet/IP), you can detect up to 90% of all anomalies that could lead to failures in advance. At its core, the CMMS consists of a diagnostic instance for the network and a diagnostic instance for the applications. The data is then visualised, configured and managed in the central maintaining software PROmanage NT.

The condition monitoring harvest:

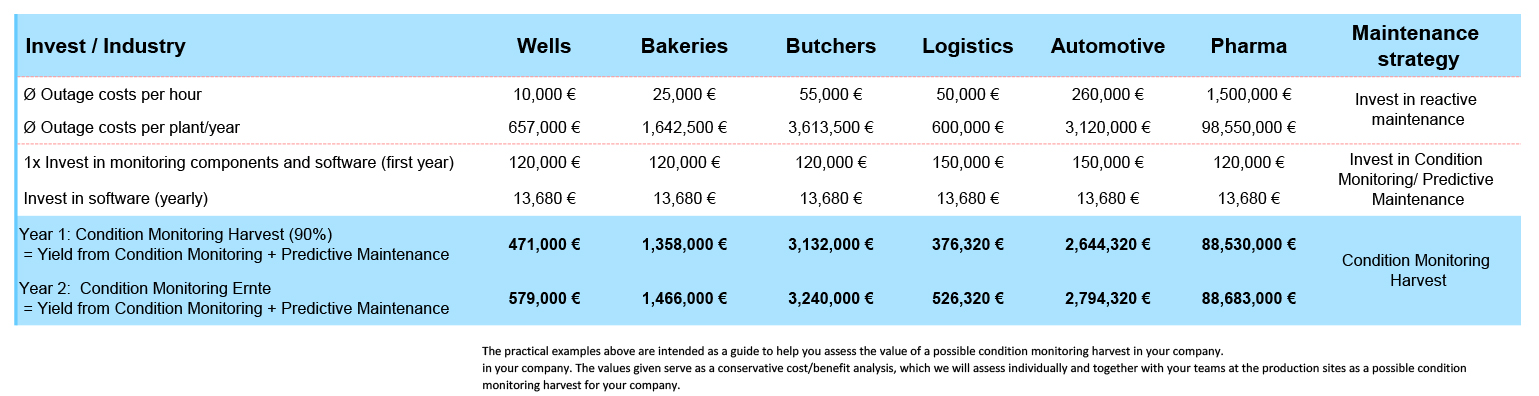

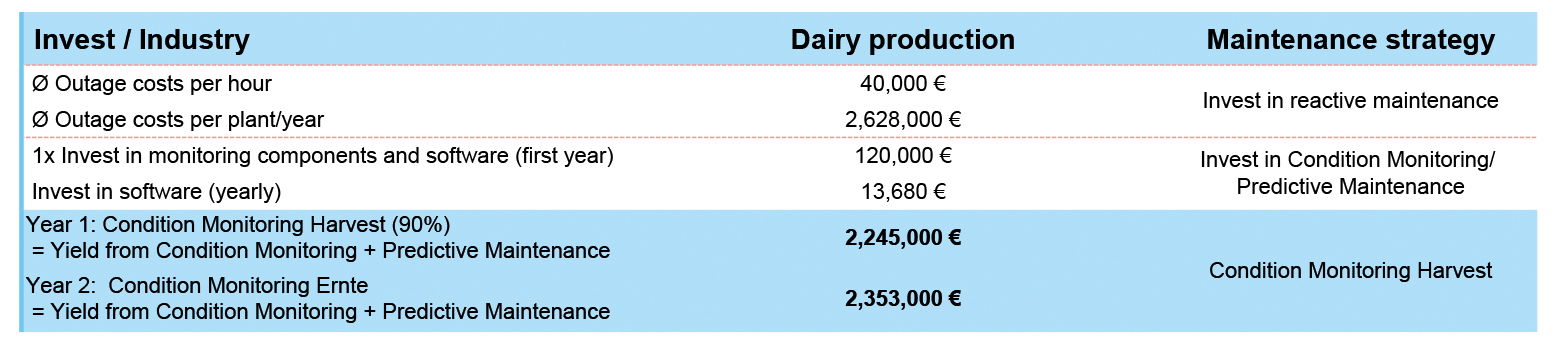

You can leverage this effectiveness potential from your production facilities

Production plants must run undisturbed and without downtime in order to exploit their full performance potential. Every minute of downtime costs money. Depending on the branch of production, a plant can quickly incur 6-digit sums per year, or even significantly more depending on the industry.

An investment in a condition monitoring system including predictive maintenance analytics with the aim of anticipating and avoiding such failures is significantly cheaper and has an immediate effect on results.

This is shown by the following examples:

For PROFINET and Ethernet/IP

For PROFIBUS

The bottom line is:

The Condition Monitoring Management System (CMMS) beats the reactive maintenance strategy.

→ Return on investment in many cases after only 7 months

How condition monitoring improves your overall equipment effectiveness (OEE)

With a sophisticated condition monitoring management system for OT networks, almost all potential reasons for failure of a production plant can be detected and processed in a structured manner. This analytics, hardware that is necessary anyway and software that is easy to implement help to increase OEE (Overall Equipment Effectiveness) - even in medium-sized companies. A quick return on investment and the know-how supplied make the CMMS ready-to-use.

► This makes an improvement in OEE of between 4.4 and 5.0% possible. A strong argument for your boss

Detecting network-related reasons for failure

20% or rather 90%?

The Condition Monitoring Managment System (CMMS) by Indu-Sol

for OT networks with PROFINET and EtherNet/IP

Intelligent components in perfect interaction

PROmesh Managed Switches

They detect anomalies through communication and environment monitoring with the following features:

- Errors

- Discards

- Network load

- Cable diagnostics

- EMC monitoring

- 24V monitoring

- TCP-IP retransmission

- Data analysis of environmental sensors

- Security functions: Firewall + detection of new devices

PROFINET-INspektor NT - passive analysing tool

It detects anomalies by monitoring the application such as PROFINET and Ethernet/IP with the following condition monitoring features:

- Network load

- Device diagnostics

- Device breakdowns

- Logouts

- Telegram gaps

- Error telegrams

- Jitter

- Security functions: Detection and alerting new devices

- Cyclic topology scan

- Automated device list and port statistics

PROmanage NT management software

The software is used to configure and manage the smart devices and data with the following features:

- Evaluating and analysing all applications and Ethernet networks

- Configuration management

- Live network topology incl. network status display

- Individually configurable alert management

- Data archiving up to 1 year

Would you like to learn more?

Get your virtual coffee session with one of our experts!

Michael Röhler

OT network specialist | Indu-Sol

Your specialist for condition monitoring and the digitalisation of modern and resilient industrial networks that fit your requirements.

I support you in improving your plant availability and in uniting the various interests of maintenance, production management, operations management and corporate management.

Choose your desired date

We arrange

an appointment,

that suits you.

On your computer

Online session

digital, modern

and save.

Your topic, our expert

Choose your

preferred topic

and tasks.

With maximum relaxation

Well-being

through a good

coffee.