Network Monitoring and Management for Industrial Plants

Condition-focused maintenance, remote management, avoiding power failures, etc.

Stable and reliable operation is a top priority for any industrial plant. While it may sound quite trivial at first, it can turn into a great challenge for plant operators and maintenance personnel. Most faults can be found at an early stage – provided that a permanent diagnosis or monitoring system (permanent network monitoring, in short: PNM) is running in the plant network.

What are you looking for?

Quick links and list of subjects

Explanation / Advantages

Implementation / Options

Consulting / Personal advice

Choose your plant network

Flexible Monitoring Solutions for Industrial Networks

Individual. Across Networks. Scalable.

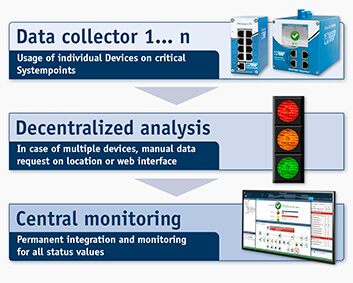

It might feel different at first, but permanent network monitoring (in short: PNM) has many possible implementations. You can use a network monitoring system that can be expanded at any time based on your needs and budget.

Monitoring solutions begin at a single analysis data collector, such as the PROFINET-INspektor® NT ar a PROmesh switch with integrated diagnosis function. Any number of additional data collectors can be used depending on system type, network structure, and requirements. Since these devices were also designed for independent operation, they often come with dedicated web-based monitoring applications. This, or manual reading of long-term data stored on the device, permits detailed evaluation at any time.

Operators of complex or multiple systems can centralise and partially automate professional condition monitoring via the PROmanage NT network monitoring software. Stay informed about critical events automatically on top of using evaluation, thorough analysis, and long-term storage of status data of your fieldbuses and industrial Ethernet networks.

Scalable solutions starting at a single monitoring device

Scalable solutions starting at a single monitoring device

[...] In machines and plants without a monitoring system, reactions [...] are only possible when externally visible faults appear [...]. Detection and elimination of the causes will take much longer than they have to. VORTEX-Report 2019

Combination options / expansion stages

Industrial network monitoring always matching your needs

Choose between the basic combination options and start with professional network monitoring to match your requirements.

Your requirements have changed? That’s no problem since our network monitoring solutions can be freely combined and extended at need at any time.

Software-based network monitoring without additional hardware

Basic monitoring solution for Ethernet-based industrial networks with managed switches

Application-comprehensive OT monitoring

(free combination possible)

Integrated monitoring for heterogeneous networks – from PROFINET to AS interface.

Device-based monitoring for Ethernet and fieldbus (also as stand-alone solutions)

Monitoring units for PROFINET, PROFIBUS, etc. – Can be used on their own or in combination.

Would you like to learn more? Request a free consultation by phone, web session or on site.

Example from Practice – BAUR Versand: Monitoring (PNM) in the Industrial Environment

Baur Versand GmbH & Co KG Altenkunstadt

Networks used: PROFIBUS, PROFINET, ASi

"Ten minutes of downtime are virtually impossible to compensate for within a day." (H. Fiedler, BAUR Versand)

The plant monitoring has grown along with demands

- Sporadic interferences and downtimes after commissioning of the loading sorter

→ among other things with effects on upstream stations and processes - On-site measuring deployment by Indu-Sol

→ commissioning of the first PROFIBUS INspektor units - Gradual expansion of permanent network monitoring to all (new) systems

→ currently 33 measuring and analysis units in use - Introduction of the central PROmanage® NT monitoring software

→ ability of centrally viewing the overall condition of all networks based on requirements - Gradual shift to PROFINET-INspektoren® NT units

→ new functions simplify network monitoring and safety

PNM advantages at past events (excerpt)

- Support, evidence, review of removal of sporadic plant errors

→ permitted faster remedy by the plant constructor service team - Function inspection after subscriber exchange within the scope of a PROFIBUS-Retrofit

+ Ongoing inspection in operation - Central monitoring of all analysis devices in PNM software PROmanage® NT

- Permanent condition monitoring with low personnel resources

→ thanks to automatic alarm function - Targeted maintenance and repair

→ monitoring system reports where there are any errors in the system network - Current and historical network conditions in view at all times

→ permits seamless tracking in shift operation

What is Permanent Network Monitoring/Condition Monitoring?

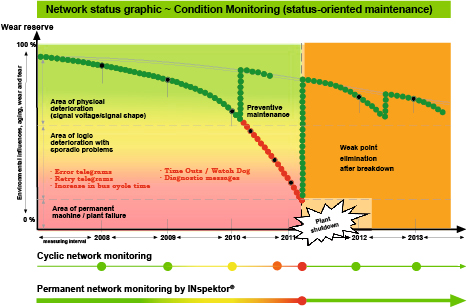

Maintenance of your systems is clearly simplifiedby seamless network condition recording. Physical and logical system values can be recorded and evaluated in a similar manner as for targeted (maintenance) measurements with simple measuring clamps. However, since data are acquired continually, in detail, and even at several measuring points in parallel, maintenance staff can detect irregularities speedily to eliminate the cause early on and permitting cost-efficient, condition-based maintenance.

7 Reasons Why You Should Be Using Permanent Network Monitoring as Well

1. Predictive, condition-oriented maintenance

Put an end to (needless) maintenance by schedule. Monitoring will tell you exactly where any deviations happen, and which parts require maintenance. Repairs become the exception.

2. Correct assessment of fault reserves

Always keep the entire condition of your plant in view to effectively avoid entering a critical fault area.

3. Ensuring network stability

Permanent documentation of your network load will permit precise assessment of your network condition. In contrast to cyclic random sample measurement, bottlenecks can be recognised and avoided in advance.

4. All condition values at a glance

Are all physical and logical quality values observed? How is my network doing? A look at your monitoring solution will give you all the answers you need.

5. Seamless condition data

The recorded measured values make service staff aware of any deviation. All events of the last 12 months are documented to the minute for optimising cause research.

6. Relief by alarm function

Stay flexible even if you are not actively tracking the network condition. The integrated alarm function will inform you, among other things by email, text message, OPC, when there is a need for action.

7. Save time and money – with remote diagnosis

Faster help in emergency – where necessary, external service engineers can get an idea of the condition of your plant even before they come to site and start their work without delay upon arrival.

Consulting: Finding the Best Monitoring Solution for Your Industrial Network!

Notice: Your desired appointment will be scheduled after your request for advice is received. Please select your desired mode of contact before submitting the form.

Professional advice

– as individual as you are

Our expert team will develop the optimal monitoring solution together with you – matching your plant and your budget.

Adjusted to your needs from the first – choose your desired mode of advice:

1. Free advice – phone/web session

Ideal for getting information + basic advice

Do you have any questions about the perfect entry into permanent network monitoring? Get comfortable and simple advice by phone or web meeting at your desired time. (Consultation time max. 1 h)

2. advice on site (by agreement)

Ideal for your project preparation/planning

Are you looking for a central monitoring solution for (multiple) plants that is customised to your requirements? This option is the right choice. We or an authorised partner near you will visit your site. After getting an initial impression of your plant and requirements, we will present suitable implementation options to you. (Price and duration by agreement)