PROFINET Agent

Efficient commissioning with “Agent Blond” - New data source for the PLC diagnostic buffer

PROFINET Diagnostic Agent simplifies commissioning

During commissioning, the focus is on functional and quality testing of individual system components. Under time pressure, however, unexpected and non-reproducible anomalies in PROFINET communication often occur. This is not unusual, as shown by the “bathtub curve” in the graphic below. Still, the recurring question remains: Why now, when everything has already worked flawlessly before?

A high error rate at the beginning is not unique to electrical, mechanical, or network systems. It is a normal and necessary phase when transitioning a machine or plant into continuous operation and ensuring long-term availability. It only becomes problematic when this phase is unexpectedly prolonged - because device failures reappear at different points in the network over time. This is frustrating, time-consuming, and ultimately costly due to unexpected downtime.

Bathtub effect

Bathtub effect

To quickly remedy the situation, affected devices that the PLC reports as failed are often declared defective and replaced. Not infrequently, this cycle repeats several times until the actual cause is identified - a faulty backbone cable.

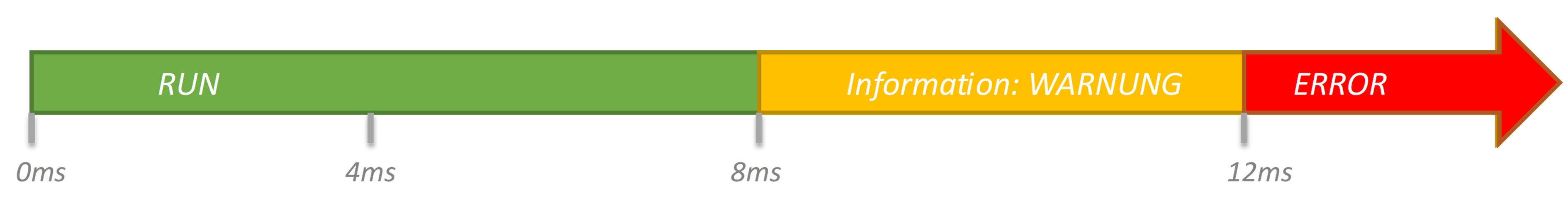

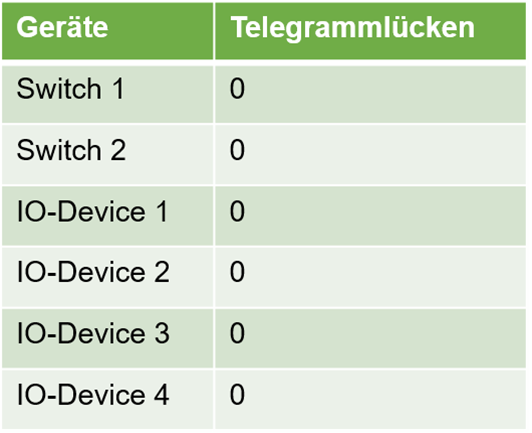

Typically, the PLC (controller) monitors the communication of the PROFINET IO devices (application level). The first place to check is therefore the diagnostic buffer, which provides extensive information. However, in this context the diagnostic buffer recognizes only two states: “working” or “not working”- in other words, green or red.

Using the traffic light metaphor, it becomes clear that the yellow range - information and warnings - is completely missing, even though parameters exist that could make this visible.

Assuming that apart from a power failure there are no truly sudden and unforeseeable faults, the question arises: How can a failure be predicted, or at least more precisely localized and described?

Telegram analysis cycle with PROFINET Agent “Agent Blond”

Agent Blond makes information usable for the PLC.

This is where the PROFINET Agent “Agent Blond” from Indu-Sol comes in. It is integrated into the network as a non-intrusive measurement point to monitor network communication (a silent listener). Such a measurement point (TAP) is already installed in many systems - so this in itself is nothing new. The difference lies in the intelligence with which the Agent is equipped.

By integrating into the PLC configuration and utilizing the PLC diagnostic buffer, it ensures that information about abnormalities in PROFINET communication is available through the familiar reporting path in the diagnostic buffer.

How does “Agent Blond” work?

To answer this, we need to take a closer look at PROFINET communication.

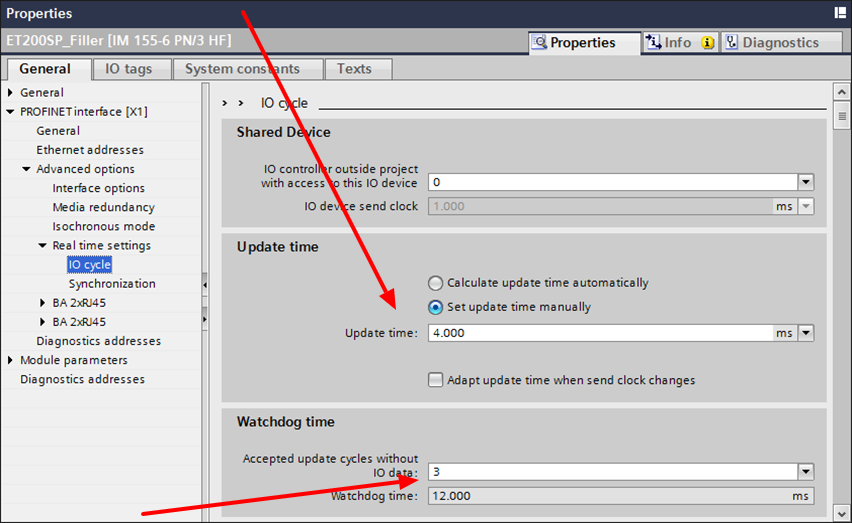

Each device in the network requires a certain transmission time to send its information (update time or cycle time). To ensure reliable transmission, the communication protocol provides an additional time buffer (response monitoring time - watchdog), usually set to three times the update time.

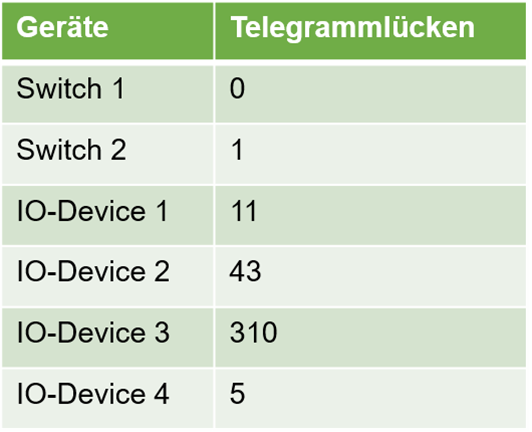

If data transmission does not succeed within this buffer, the system switches to a safe state - the communication with the device is terminated. Traceability is achieved by detecting telegram gaps or packet loss, since every missed transmission leaves a gap at the receiver.

In the PLC’s default settings, up to three gaps are tolerated and therefore not recorded in the diagnostic buffer. In other words: “Everything is fine - no irregularities.” Only when more than three telegram gaps occur does the system switch to an error state (terminating communication with the device). The trigger for this is the watchdog being exceeded.

Excerpt from the TIA Portal: PROFINET default setting

Update time: Defines the transmission interval of each device.

Response monitoring time:

A multiple of the update time, it defines how long the device tolerates missing data before switching to a safe state

The occurrence of a telegram gap is a reliable early indicator and therefore an important piece of information for assessing PROFINET data traffic quality. A device-related message provides a clear view of the network topology, making it possible to precisely identify the cause (faulty cable, backbone connection, connector, device) or the origin (EMC issues). Equally important is the ability to verify the success of a device replacement through before-and-after comparison.

Installation location of the PROFINET Agent in the PROFINET network

Product Details

See for yourself!

Test the PROFINET Agent free for 8 weeks. Request it now!

Media library

Downloads

Be part of the future of network commissioning!

Take advantage of Agent Blond and optimize your commissioning processes for the long term. Contact us for a free strategy consultation with our network experts.

GOOD TO KNOW - clear and concise!

PROFINET - The Movie | Technology Made Easy

Take a look!